The Ultimate Guide to Plastic Packaging for Cosmetics

Ever stood in the skincare aisle, staring at rows of dreamy creams and glossy bottles—only to wonder why some brands look like a million bucks while others seem slapped together with duct tape? That magic (and madness) starts way before the shelf. Plastic packaging for cosmetics isn’t just about holding goop—it’s about keeping formulas fresh, dodging leaks mid-shipment, and catching eyeballs in under three seconds.

Now here’s the kicker: picking the right plastic ain’t as simple as “grab a bottle and go.” What holds your tinted serum might melt your foaming cleanser. And don’t even get me started on shipping overseas—one wrong lid and your coconut scrub becomes cargo soup.

If you’re sourcing 10,000 units or more, you’re not just buying containers—you’re making a business decision that affects everything from compliance audits to how TikTok influencers unbox your product. This guide cuts through the fluff so you can make smart calls without needing an engineering degree or psychic powers.

Reading Notes on Plastic Packaging for Cosmetics: From Material Magic to Budget Logic

→ Material Types Matter: PET offers clarity and recyclability, HDPE is tough and moisture-resistant, LDPE is flexible for squeeze tubes, PP balances strength and affordability, while acrylic delivers luxe appeal.

→ Formula Protection First: HDPE and PP plastics provide essential barrier properties against moisture and oxygen—key to preserving active ingredients in cosmetics.

→ Regulatory Readiness Required: Your packaging must meet industry standards through certifications that ensure safety across global markets.

→ Recycled Plastics Are Viable: With proper purity testing, recycled PET can be safe and sustainable—just beware of leaching risks in HDPE/LDPE containers.

→ Budget-Smart Choices Exist: Stock PP jars offer volume discounts; flip-top caps cut costs; sleeve labeling gives a polished look without high decoration fees.

Types Of Plastic Cosmetic Packaging Materials

From sleek jars to flexible tubes, the right plastic can make or break cosmetic packaging. Here’s a breakdown of the most common types used today.

PET plastic

When it comes to clarity and recyclability, PET plastic wins hands down.

- Transparent like glass but way lighter.

- Used in both premium and budget skincare lines.

- Often found in toner bottles, facial mist sprays, and clear body lotions.

- It resists moisture and oxygen — keeping formulas fresher longer.

- Brands love its compatibility with vibrant labeling and printing techniques.

Because it’s recyclable, many eco-conscious companies lean toward polyethylene terephthalate, especially for high-volume items like shampoos or micellar waters. It’s also sturdy enough to survive long shipping routes without cracking — perfect for global beauty brands chasing shelf appeal and sustainability at once.

HDPE plastic

You’ve definitely handled HDPE plastic if you’ve ever squeezed out sunscreen or lotion from an opaque bottle.

• Strong resistance to chemicals — ideal for active skincare formulas.

• Sturdy build means fewer leaks during travel or rough handling.

• Typically used in white or colored bottles that block UV light.

Grouped by use:

— Bottles: Moisturizers, body lotions, cleansers

— Jars: Hair masks, thick creams requiring scoop application

— Pumps & closures: Durable tops that withstand repeated use

Thanks to its toughness and recyclability, high-density polyethylene is a go-to for everyday personal care products that need both protection and practicality.

LDPE plastic

Flexible yet tough — that’s what makes LDPE plastic a favorite in the beauty aisle.

Step-by-step how it works:

- Start with its squeezable nature — perfect for toothpaste-like tubes.

- Add low cost — great for large-scale production.

- Mix in chemical resistance — it won’t react with most cosmetic ingredients.

- Finish with easy molding properties — ideal for custom shapes and fun designs.

This combo makes low-density polyethylene popular in haircare tubes, gel-based products, and kids’ bath items where playful packaging matters just as much as function.

PP plastic

This one’s a bit of a utility player in the world of plastic packaging for cosmetics, thanks to its well-rounded properties.

• Commonly used in jars due to heat resistance during hot-fill processes

• Also seen in caps because it holds threads well without warping over time

According to Mintel’s 2024 Packaging Innovation Report, “Polypropylene-based containers are rising fast among mid-tier brands seeking durability without sacrificing design flexibility.”

That’s no surprise when you consider how versatile this material is — from deodorant sticks to compact foundation cases, PP plastic handles it all without breaking the bank or melting under pressure.

Acrylic plastic

Think luxury? Think acrylic plastic.

Short bursts on why it’s loved:

— Looks like glass but won’t shatter if dropped on tile floors.

— Creates high-end feel without high-end fragility issues.

— Often used in compacts, lipstick cases, and upscale jars for anti-aging creams.

Its glossy finish gives premium branding an edge while still being lighter than actual glass containers. That “click” sound when closing an acrylic jar? That’s the sound of elegance meeting functionality — something every prestige brand craves when choosing their cosmetic container game plan involving materials like polymethyl methacrylate (PMMA) over conventional options like PET or HDPE plastics.

Five Critical Factors Impacting Plastic Packaging Material Choice

Choosing the right plastic packaging for cosmetics isn’t just about looks—it’s about performance, safety, and staying eco-conscious. Let’s break down what truly matters.

Preserving Formulas: Barrier Properties of HDPE and PP Plastics

- HDPE resists moisture—perfect for keeping creams stable.

- PP Plastics block oxygen better, ideal for serums or actives.

- Both materials extend shelf life by guarding against air and water exposure.

• Think of it like armor for your formulas—these plastics keep ingredients potent and safe from spoilage.

• Not all plastics play nice with every formula; compatibility testing is key to avoid reactions that could mess with consistency or color.

Essential Regulatory Compliance and Quality Certifications

- Products must align with FDA or EU cosmetic packaging regulations—no cutting corners here.

- Look for certifications like ISO 22716 or GMP—they guarantee manufacturing quality and traceability.

✓ If you’re exporting globally, each region has its own rules—Japan requires different safety data than the U.S., for example.

✓ Staying compliant means fewer headaches during customs checks and less risk of product recalls.

Topfeelpack ensures all its packaging meets international regulatory compliance standards without compromise.

Durability Under Pressure with Makeup Products

Lipsticks melting? Compacts cracking in transit? That’s where good material choice saves you big time.

• Choose high-impact resistant materials like ABS or reinforced PP to handle drops, pressure, and temperature swings during shipping.

• For liquid makeup, opt for flexible yet strong tubes that bounce back after squeezing without leaking—a must-have trait tied to solid pressure resistance.

Pro tip: Always test packaging under simulated transport conditions before going full-scale production.

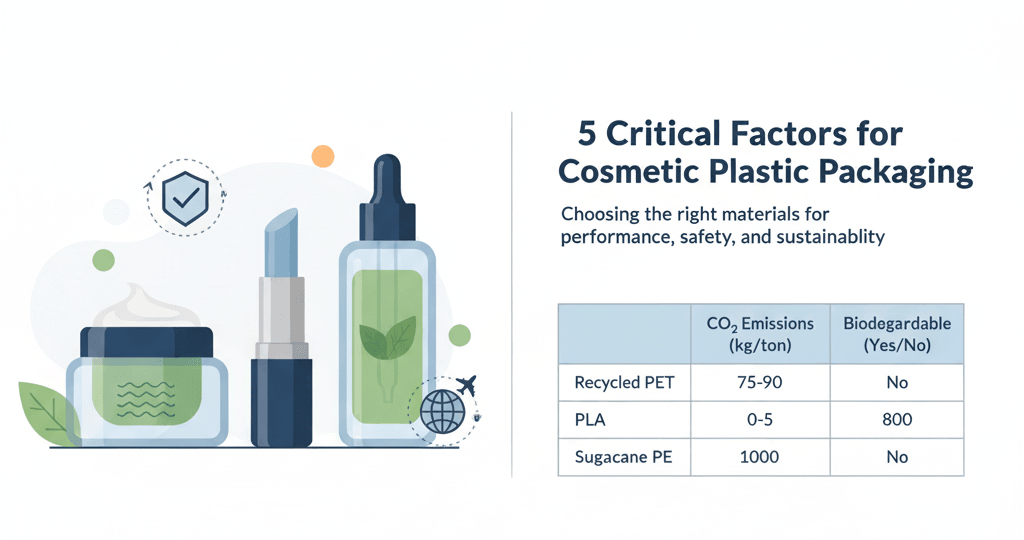

Sustainability of Recycled PET and Sustainable Materials

| Material Type | Recyclability (%) | CO₂ Emissions (kg/ton) | Biodegradable |

|---|---|---|---|

| Virgin PET | 100 | 2,500 | No |

| Recycled PET | 100 | 1,500 | No |

| PLA (Bioplastic) | 80 | 800 | Yes |

| Sugarcane PE | 90 | 950 | Yes |

Using recycled PET, brands can cut emissions while still offering durable bottles that look sleek on shelves.

Consumers care about sustainability now more than ever—and they’ll notice if your brand does too.

Don’t forget end-of-life planning: make sure your packaging is easy to recycle curbside or through take-back programs.

The Truth About Recycled Plastic in Cosmetic Bottles

Sustainability isn’t just a buzzword anymore—it’s a purchase driver. More brands are turning to recycled plastics like PET and HDPE for plastic packaging used in cosmetics. But what’s safe, and what’s marketing fluff? Here’s the breakdown.

Recycled PET (rPET) for Cosmetic Bottles

Recycled PET is on the rise—and for good reason.

• It maintains clarity for premium display.

• It’s sturdy and resists breakage during shipping.

• It’s readily available worldwide at scale.

Is it safe for skincare?

Yes—when sourced responsibly. Here’s why it passes the test for cosmetic use:

• These recycled containers must meet strict FDA regulations, especially when used with creams, serums, or toners.

• Some manufacturers go an extra mile by sourcing only food-grade post-consumer resin to ensure material safety.

PET’s recyclability is great—but only if it doesn’t mess with product integrity. That’s why brands using this type of plastic packaging for cosmetics often include third-party certifications proving low contaminant levels. The bottom line? If it’s going near your pores, it better be clean.

Chemical Leaching Studies in HDPE and LDPE Containers

You don’t want your moisturizer soaking up unwanted chemicals from its container—and neither do scientists. Here’s what studies say about chemical migration from HDPE and LDPE:

— Independent labs routinely test these plastics under simulated storage conditions, assessing how much chemical leaching occurs over time.

— Results show that properly processed recycled HDPE has leach rates below 0.001 mg/L for most common contaminants—even under elevated temperatures.

— LDPE tends to fare slightly better with oil-based formulations due to its lower permeability profile.

— According to a 2024 report by Euromonitor International, “recycled high-density polyethylene used in skincare jars shows no statistically significant increase in exposure risk compared to virgin plastic.”

So while concerns about leaching aren’t baseless, well-treated recycled plastics hold their own just fine under scrutiny—especially when paired with stable formulas like lotions or gels.

Closure Compatibility: Dropper and Child-Resistant Caps

Getting a secure closure on a recycled bottle isn’t always plug-and-play—it takes precision engineering:

Step 1: Assess the thread integrity of the neck area post-molding; even slight warping can ruin cap alignment.

Step 2: Test various types of closures like Droppers or push-down-and-turn caps on sample batches made from different recycled resins.

Step 3: Use pressure chamber simulations to evaluate seal performance over time—this helps prevent leakage during shipping or long shelf stays.

Step 4: Check compliance with child-resistant standards through certified testing labs before going into production mode.

When working with recycled materials, especially those used for sensitive items like serums or oils, ensuring that closures work seamlessly is non-negotiable. A poor seal doesn’t just mean mess—it could compromise product safety altogether.

Visual Appeal: Label Application on Colored Recycled Plastic

Colored bottles look cool—but they can be tricky when labels come into play. Here’s what usually happens:

Some adhesives don’t bond well with textured surfaces found on certain colored recycled containers; labels may peel at corners within weeks of application.

Print clarity can suffer too if the background color clashes with the ink tones; white ink on dark green plastic? Not always a hit visually—or legibly!

Glossy finishes tend to enhance brand appeal but may require additional surface treatment before label application sticks properly across curved areas of jars or tubes made from reused plastic blends.

All these quirks affect how consumers perceive quality at first glance—which is why brands investing in sustainable plastic packaging for cosmetics also spend time refining label placement strategies tailored specifically for colored post-consumer materials.

Facing Budget Constraints? Affordable Plastic Packaging Solutions Available

Looking to cut costs without cutting corners? These budget-friendly plastic packaging for cosmetics options strike the perfect balance between quality and savings.

Stock PP Plastic Tubes and Jars for Volume Discounts

Bulk buying doesn’t mean boring choices—stock options can still look sleek and professional:

- PP plastic is lightweight, durable, and cost-effective—ideal when ordering thousands.

- Choose from a variety of tubes and jars, pre-molded to standard sizes that skip custom tooling fees.

- Volume discounts kick in fast, making larger orders significantly cheaper per unit.

- Great fit for skincare or haircare lines looking to scale without overspending.

- Topfeelpack offers flexible MOQ tiers so even smaller brands can take advantage of economies of scale.

For any brand scaling up their plastic cosmetic packaging, this route keeps both your margins and presentation on point.

Sleeve Labeling on Transparent and White Plastics

No need to splurge on direct printing—sleeve labeling does the job with flair:

- Works perfectly with both transparent plastics and crisp white plastics, giving a clean canvas every time.

- Customizable in full color, these labels wrap around containers seamlessly.

- No extra tooling or setup charges required—just design, print, apply.

- Durable enough to resist moisture, oils, and daily wear common in cosmetic use.

Ideal for indie beauty brands wanting vibrant branding without heavy print costs attached to traditional methods.

Flip-Top and Screw Caps to Cut Closure Costs

Short-term savings meet long-term reliability when you choose tried-and-tested closures:

• Basic doesn’t mean boring—standardized flip-top caps still offer sleek usability at a fraction of the price.

• Go with classic screw caps, which are easy to source, universally compatible, and super budget-friendly.

These closure styles pair well with most forms of plastic packaging used in cosmetics, especially cleansers or lotions where function matters more than fancy mechanics.

Custom Color Matching Without Custom Mold Fees

Want your brand’s signature hue without shelling out big bucks?

Multiple benefits come bundled here:

- You get full-spectrum custom color matching, even on small runs.

- Skip the mold fees entirely by using existing container shapes with new pigmentation blends.

- This works across jars, bottles, tubes—you name it—and helps keep visual branding consistent across SKUs.

- Especially useful when launching limited editions or seasonal shades within your product line.

Great news: You don’t have to sacrifice identity just because you’re watching your spend.

Affordable Cosmetic Packaging Options That Don’t Look Cheap

Sometimes “affordable” gets confused with “low quality.” Let’s break that myth wide open:

• Matte finishes on standard tubes can elevate look instantly while keeping production costs low.

• Pair basic containers with metallic foil sleeve labels—instant glam at minimal expense!

By combining smart design elements with off-the-shelf components like jars or tubes made from durable plastics, you get high-end appeal without blowing your budget on custom molds or exotic materials.

How Topfeelpack Helps Brands Stay Within Budget Without Compromise

Here’s how one company makes it all work:

- Offers massive selection of pre-made packaging formats tailored specifically toward cosmetic needs—from skincare jars to serum pumps.

- Allows clients access to bulk pricing tiers even at relatively low MOQs—a game changer for startups trying out new lines.

- Provides optional services like label application or color matching so brands don’t have to juggle multiple suppliers just to stay under budget.

Topfeelpack makes affordable feel premium—and lets you focus on what really matters: building killer products that look as good as they perform across any shelf space.

Combine Cost Savings With Visual Consistency Across Product Lines

If you’re launching multiple SKUs under one brand umbrella…

Group these strategies together:

• Use uniform container shapes like round PP jars across lines; only change colors via label wraps or pigment blending.

• Stick with standard closures such as screw caps but differentiate formulas through unique cap colors or finishes like soft-touch matte vs gloss plastic textures.

This approach keeps production streamlined while allowing each product its own vibe within a cohesive collection—a win-win when managing tight budgets across growing catalogs in today’s competitive beauty market landscape.

FAQs about Plastic Packaging for Cosmetics

What types of plastic are most common in cosmetic packaging?

Each type brings its own personality to the shelf. PET is clear and crisp—perfect for serums that want to show off their glow. HDPE brings strength and stability. LDPE is perfect for squeezable plastic cosmetic packaging like tubes. PP brings affordability with surprising durability. Acrylic? That’s your high-gloss option.

Is recycled plastic safe for skincare and beauty products?

Yes—especially recycled PET when properly processed. Many brands use rPET bottles for toners, micellar waters, and body sprays. HDPE-based jars and containers (when tested for purity) perform well for lotions or hair masks. Remember: safety comes first. If you’re using recycled plastics in cosmetic plastic packaging, always source from certified suppliers and confirm compliance testing.

What’s the best closure: flip-top, screw, or pump?

Depends on the product. Flip-top caps are simple and budget-friendly for cleansers or travel-size items. Screw caps are universal and reliable. Pumps are more premium-feeling—great for lotions and serums. For eye serums or facial oils, brands often prefer droppers for precise dosage.

How can I keep costs down without sacrificing aesthetics?

Use stock bottle shapes with customized label wraps. Sleeve labeling is a great way to get full-color coverage without expensive tooling. White or transparent bottles with clean typography bring premium vibes without premium costs.

I want sustainable packaging—what should I prioritize?

Go for recyclable options like PET and HDPE. Choose mono-materials where possible. Plan for end-of-life: make sure labels don’t interfere with recycling streams and that caps/closures can be separated. And if you’re in no-mess serum territory, consider reusability where it makes sense.

Final Takeaway:

Choosing plastic packaging for cosmetics isn’t guesswork—it’s strategy. Understand your formula, pick the right material, keep compliance tight, and don’t ignore the label-and-closure details. Whether you’re indie or enterprise, the right packaging doesn’t just hold your product—it sells it.

References

- [PET: Polyethylene terephthalate - NETZSCH Polymers - https://polymers.netzsch.com/Materials/Details/27]

- [Variables that Affect/Control HDPE Oxygen Transmission - LyondellBasell - https://www.lyondellbasell.com]

- [PE Cosmetic Tubes Guide (LDPE vs. MDPE vs. HDPE) - LuxeTubes - https://luxetubes.com/pe-cosmetic-tubes-guide/]

- [Polypropylene Natural Data Sheet - Direct Plastics - https://www.directplastics.co.uk]

- [Polymethyl Methacrylate (PMMA) - SpecialChem - https://www.specialchem.com]

- [ISO 22716: Cosmetics — Good Manufacturing Practices (GMP) - ISO - https://www.iso.org/standard/36437.html]

- [Cosmetics Laws & Regulations - FDA - https://www.fda.gov]

- [EFSA: Plastics and Plastic Recycling - https://www.efsa.europa.eu/en/topics/topic/plastics-and-plastic-recycling]

- [16 CFR Part 1700 - Poison Prevention Packaging (eCFR) - https://www.ecfr.gov/current/title-16/chapter-II/subchapter-E/part-1700]

- [Regulation (EC) No 1223/2009 - EUR-Lex - https://eur-lex.europa.eu/eli/reg/2009/1223/oj/eng]