Packaging Surface Treatment Process: Screen Printing

We introduced the packaging molding method in “From the Molding Process to See How to Make Cosmetic Plastic Bottles“. But, before a bottle is placed on the store counter, it needs to go through a series of secondary processing to make itself more design and recognizable. At this time, the package surface treatment process is needed. Common surface treatment processes for packaging materials include printing, painting, electroplating, and laser carving. The printing process can be divided into screen printing, pad printing, hot stamping, transfer printing (thermal transfer, water transfer).

In this article, let’s start with silk screen printing and take everyone into the world of printing technology. Regarding screen printing, there is a long-lived saying: In addition to water and air, any object can be used as a substrate. Although it sounds a bit exaggerated, it is not limited by the material to be printed, which does make it a very wide range of applications.

What is screen printing?

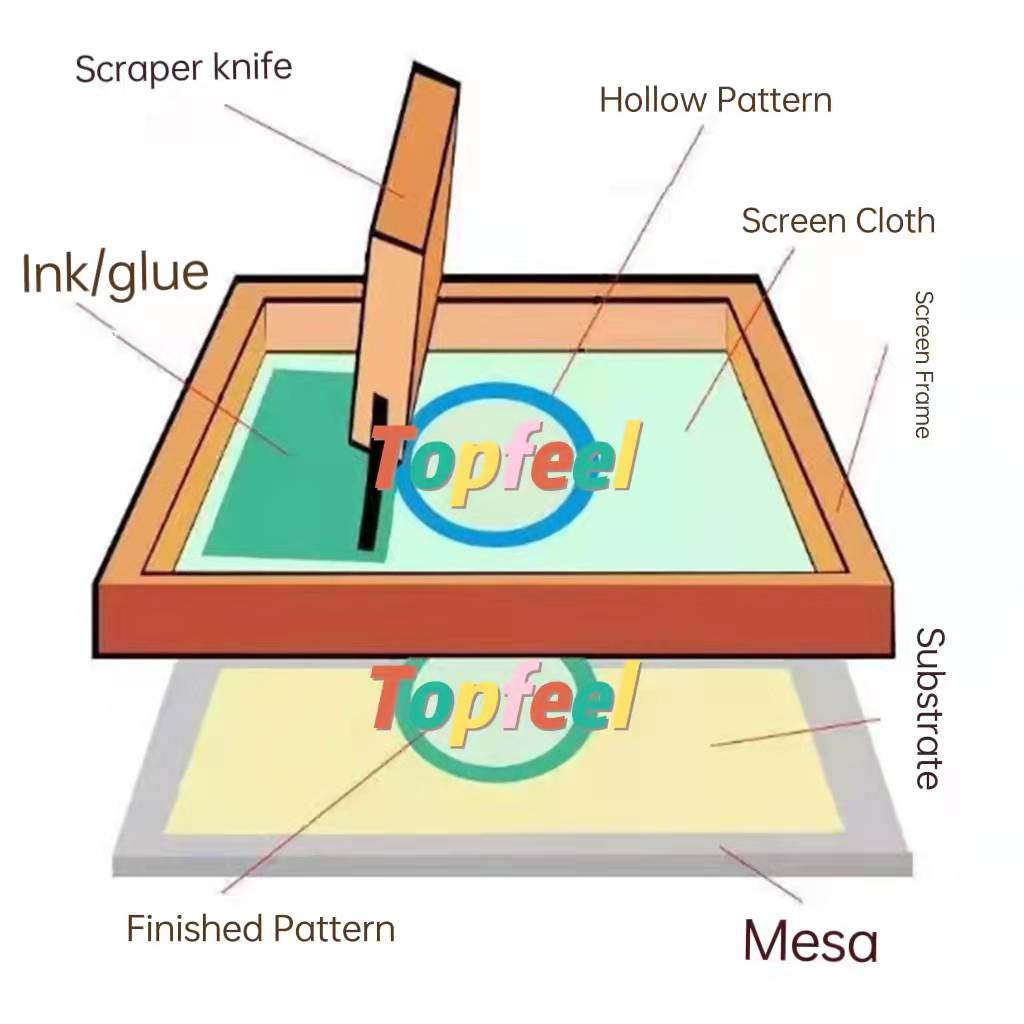

To put it simply, screen printing uses the principle that the graphic part of the screen printing plate can pass through the ink, and the non-graphic part cannot pass through the ink. When printing, pour ink on one end of the screen printing plate, and use a squeegee to apply a certain pressure to the ink part on the screen printing plate, and at the same time move towards the other end of the screen printing plate at a constant speed. The ink is moved from the picture by the squeegee The mesh of the text part is squeezed onto the substrate.

It is an ancient and modern printing process. As early as the Qin and Han dynasties of more than two thousand years of money in China, the method of stamping was introduced. Placed in modern times, screen printing is favored by many artists due to its image reproducibility, ease of operation, and manual operation.

Relying on the silk screen technology, the popular “screen print” has become a favorite way of creation by artists.

What are the characteristics of screen printing?

1. It has a wide range of uses, and the material of the substrate is not restricted.

Screen printing can not only print on flat surfaces, but also on curved, spherical, and concave-convex surfaces.

On the other hand, almost all materials can be screen printed, including paper, plastic, metal, pottery and glass, etc., regardless of the material of the substrate.

2. It can be used for colorful silk screen printing, but it is more difficult to register

Screen printing can be used for multi-color screen printing, but each printing plate can only print one color at a time. Multi-color printing requires multiple plate making and color printing. Color registration has relatively high technical requirements, and it is inevitable that there will be inaccurate color registration.

In general, silk screen printing is mainly used for printing of color blocks, mainly monochrome, used for some partial and small-scale patterns and LOGO.