Airless Lotion Pump: Step-by-Step UV Coating Protection

Shield your formulas in style—airless lotion pump packaging that laughs at drops, defies UV, and saves brands from costly returns.

Your skincare line’s got the goods—but if your packaging cracks under pressure, customers won’t stick around to find out. That’s where an airless lotion pump with UV coating swagger steps in. It’s not just about looking pretty on a shelf—it’s about shielding your formula from light, air, and the occasional purse-drop disaster.

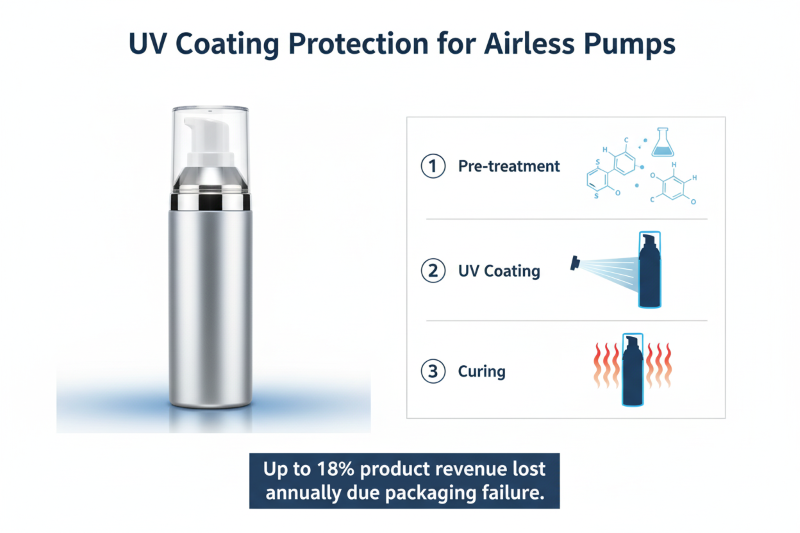

Most folks don’t think twice about what makes a bottle glow like glass or resist peeling after months in a steamy bathroom. But behind that slick finish? A three-step process that turns plain acrylic into packaging royalty—starting with pre-treatment magic and ending in a flawless cure that even 50ml workhorses can wear proud.

Truth is, brands lose up to 18% of product revenue each year due to returns tied to poor container performance (Source: 2024 Topfeelpack Materials Lab). That’s not just money walking away—it’s brand trust crumbling one cracked cap at a time.

Reading Notes for Radiance: Airless Lotion Pump Protection Unlocked

➔ Acrylic Pre-Treatment Essentials: Improve UV bonding with plasma or flame treatment to ensure long-lasting adhesion on airless pump mechanisms.

➔ Gloss & Color Harmony: Achieve high-end aesthetics through transparent color matching and glossy surface coating techniques.

➔ UV Cure Precision for 50ml Champions: Fine-tune curing times to eliminate surface flaws in popular 50ml lotion dispenser pumps.

➔ Material Cost Comparison Smarts: Understand break-even points between acrylic and polypropylene options to balance price with performance.

➔ Scale-Up Savings Strategy: Larger filling capacities like 30ml and 100ml reduce per-unit costs while maintaining premium function.

➔ Metallic Finish ROI Advantage: Choose metallic coatings over basic paints for higher perceived value and brand differentiation.

➔ Silk Screen UV Alternative Tip: Consider silk screen printing as a budget-friendly option that still offers solid UV protection benefits.

3 Key Steps To Uv Coat Airless Lotion Pump

Getting a smooth, high-gloss finish on an air-free cosmetic pump? It’s all about the prep—here’s how to nail each step without breaking a sweat.

Acrylic pre-treatment for flawless UV bonding on airless pump mechanism

Before any coating magic happens, you’ve gotta get that acrylic surface ready to grip. A slick finish won’t cut it if the bond fails underneath. Here’s what matters:

- Plasma treatment: Zaps away contaminants and activates the surface with high-energy ions.

- Flame pre-treatment: Brief exposure to controlled flame oxidizes and roughens the top layer, improving grip.

- Surface tension test inks: Used right after treatment to confirm energy levels are ideal for adhesion.

- Ionized air blow-off stations: Remove micro dust without static buildup—key before UV coat application.

- Anti-static brushes: Often overlooked but vital in cleanroom environments where airborne particles ruin finishes.

These steps make sure your base layer doesn’t flake or bubble when hit with that curing light later on.

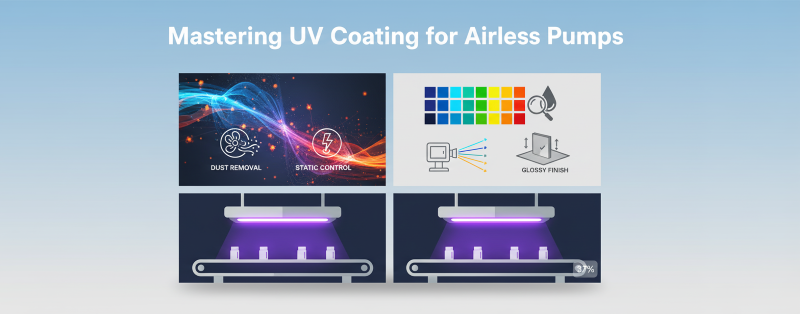

Transparent color matching & glossy surface coating preparations

Nailing color and shine isn’t just chemistry—it’s part art, part obsession. Here’s how pros get that showroom gloss:

• Begin with ultra-fine pigment dispersion using high-shear mixers; clumps are your enemy here.

• Match colors under D65 standard daylight lamps—what looks good indoors can go totally sideways outside.

• Add gloss enhancers like silicone resins in tiny increments; too much and you’ll mess up flow behavior.

Then comes testing:

- Spray samples onto test panels of identical material as your packaging.

- Flash dry under controlled humidity—moisture ruins uniformity.

- Cross-check opacity using spectrophotometers to ensure no tinting inconsistencies sneak through.

Multiple short tests beat one big failure down the line.

UV cure optimization for 50ml filling capacity lotion dispenser pump

Dialing in UV curing is where science meets timing—and it really shows in pumps sized at around 50ml, where surface area plays tricks on consistency.

- Adjust lamp intensity based on geometry—the deeper curves of a mid-sized dispenser pump body reflect light differently than flat panels.

- Use conveyor speeds tuned by rheology tests; too fast and you get tacky spots, too slow and yellowing kicks in.

As reported by Allied Market Research in early 2024, “UV-cured coatings saw a defect reduction rate of over 37% when optimized per unit volume rather than batch size.” That stat alone should make anyone rethink default settings.

Smooth coatings don’t just look better—they protect better too, especially when customers toss their skincare into bags without thinking twice.

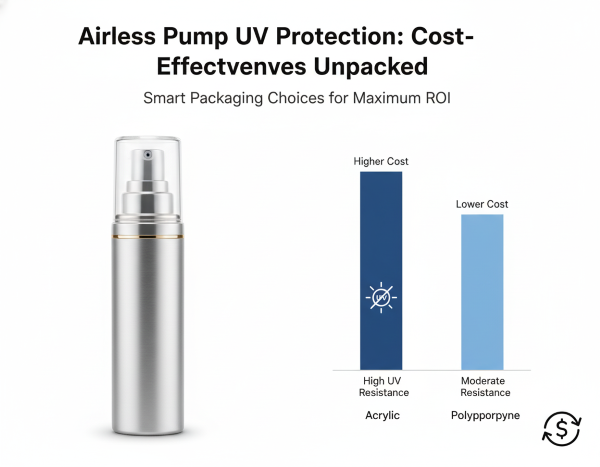

Is Airless Pump Uv Protection Cost-Effective?

Looking to get the most bang for your buck with UV-safe packaging? Let’s unpack how smart design choices can save you serious cash.

Break-even analysis for acrylic vs polypropylene material costs

- Acrylic looks fancy but costs more upfront.

- Polypropylene is cheaper and more flexible for production.

- Acrylic lasts longer under UV exposure, making it ideal for premium products.

- Polypropylene may need extra coatings, adding to long-term cost.

| Material | Avg. Lifespan | UV Resistance Rating |

|---|---|---|

| Acrylic | High | Excellent |

| Polypropylene | Medium | Moderate |

So if you’re pushing high-end lotions or serums, acrylic might pull ahead after a few production runs.

Scaling up savings with 30ml and 100ml filling capacities

You’ll see real savings when you scale up:

- A single mold run produces more units at once—lowering per-unit costs.

- Filling larger bottles like the common 100ml size reduces labor per milliliter.

- Shipping efficiency improves with fewer units needed per volume sold.

“According to Smithers Pira’s Q2–2024 packaging report, unit cost reduction through container upsizing averages around 18%.”

For brands using an airless lotion pump system, choosing bigger fills means better margins without sacrificing performance.

ROI of metallic color finishes vs traditional painting

• Traditional paint chips over time—especially under sunlight • Metallic finishes offer durability + premium shelf appeal • ROI kicks in after about five product batches

If your brand image leans luxe, metallic pays off faster than you’d think. It doesn’t just look good—it lasts longer under UV stress too.

Topfeelpack has noticed a consistent uptick in repeat orders where metallic finishes were used on their signature airless-style bottles.

Silk screen printing as UV coating protection alternative

Silk screening isn’t just about logos—it can double as protection:

→ Acts as a semi-barrier against direct light

→ Cuts down on separate coating expenses

→ Offers design flexibility without extra materials

It’s a slick way to combine branding and function into one move—especially handy if your product line uses transparent or translucent plastic containers that need some sun-shielding help.

Comparing durability across finish types and fill sizes

Grouped by fill capacity and finish type:

30ml Bottles:

• Painted Finish – Lower cost but prone to fading

• Metallic Finish – Mid-cost with solid longevity

• Screen Printed – Budget-friendly with protective benefits

100ml Bottles:

• Painted Finish – Higher material usage = higher risk of wear

• Metallic Finish – Scales well visually and functionally

• Screen Printed – Best balance of price + protection

Choosing wisely here depends on what matters more—appearance or resilience. Most brands go hybrid: screen print plus subtle metallics for max impact.

Packaging lifecycle cost comparison by material type

Let’s break it down step-by-step:

Step A: Calculate raw material cost per unit — PP wins here every time.

Step B: Add expected lifespan based on UV exposure — acrylic takes this round.

Step C: Factor rework/replacement rate — lower for acrylic = long-term savings.

Step D: Combine all above to find true lifecycle cost — not just initial spend!

When you’re deciding between clear poly containers or glossy acrylic ones, don’t forget the hidden costs that come knocking six months later when paint peels or pumps jam from sun damage.

How protective features influence resale value

Short bursts of insight:

– Items with better UV resistance tend to hold value longer during resale cycles.

– Buyers pay attention to packaging integrity—scuffs, yellowing plastics? Big no-no.

– Premium materials like coated acrylic boost perceived quality even secondhand.

That means investing upfront could mean better returns later—even if you’re not the one reselling it directly.

Impact of finish choices on consumer perception & shelf life

Here’s where style meets science:

- A shiny metallic bottle screams “luxury,” boosting perceived product value instantly.

- Matte silk-screened textures feel modern and tactile—great for minimalist skincare lines.

- Clear painted finishes look great day one… but often fade fast unless treated properly against sunlight creep.

Bottom line? The right finish doesn’t just sell—it sticks around longer too, especially when paired with smart dispensing tools like an airless lotion pump setup designed for both form and function.

Uv Coating Cracking? Single-Step Protection Solution

Cracks ruining your packaging vibe? Here’s how to armor up with smarter design and coating tweaks that keep bottles looking flawless.

Glass bottle material reinforcement using single-step UV shield

- UV shield coatings build a flexible yet strong layer across the surface, reducing microfractures during transport.

- This method works best on glass containers, especially when paired with low-expansion materials like borosilicate blends.

- Reinforcement is done during production, adding no extra steps for filling or sealing—totally seamless.

The trick is simple: apply once, protect for good. This single-layer strategy makes it easier to prevent stress lines from forming when pressure changes hit.

Soft touch surface enhancement to prevent crack lines

Adding a soft-touch finish isn’t just about aesthetics—it actually helps absorb minor impact shocks that would otherwise cause hairline splits. A few key perks:

• Adds grip and reduces slippage • Dampens vibrations during shipping • Visually hides existing imperfections

Paired with a sturdy airless pump, this combo keeps both form and function intact without compromising feel.

Custom mold design and embossing logo for durable finish

Let’s break it down into grouped essentials:

Custom Mold Design Benefits:

- Reduces weak points by eliminating sharp corners

- Supports even wall thickness across the bottle body

- Allows integration of functional parts like threaded collars

Embossing Logo Advantages:

- No added label = less peel risk under UV exposure

- Tactile branding adds premium feel without fragility

- Permanently bonded texture resists cracking around edges

Together, these features don’t just look cool—they’re built tough from the inside out.

Material synergy between coating and substrate matters more than you think

When the coating chemistry clashes with what’s underneath, cracks show up fast. Compatibility between UV curable layers and glass substrate must be dialed in precisely—especially if there’s silicone-based residue involved post-molding. One misstep here can undo every other reinforcement effort.

Why airless lotion pump designs benefit from crack-resistant bodies

Shorter actuator stems, tighter seals, and internal spring systems all rely on stable housing integrity. If the outer shell cracks:

– The vacuum seal fails fast – Product oxidation increases – Dispensing becomes inconsistent

By reinforcing bottle walls and choosing crack-resistant finishes, you make sure the entire airless system stays airtight and smooth-operating longer.

Common causes of UV coating failure on curved surfaces

- Over-curing leads to brittleness

- Inconsistent spray angle creates thin spots

- Poor adhesion due to dust contamination

- Incorrect lamp distance affecting polymerization depth

Catching these early saves loads of headache later—especially for curved jars or cylindrical pump bottles needing full wraparound protection.

Combining embossing techniques with UV topcoats for double defense

Here’s how this duo works magic together:

• Embossing gives natural texture variation that interrupts crack propagation paths • Topcoat seals embossed zones tightly without pooling into crevices • Combined effect boosts durability while keeping logos crisp over time

For brands chasing long shelf-life aesthetics, pairing both methods means fewer returns due to damaged packaging—even after months on display shelves.

Mistakes people make during post-coating handling stages

Too often folks forget that freshly coated bottles need curing time before stacking or capping:

– Rushing this step compresses uncured zones = instant microcracks later on – Using high-friction conveyors post-coat adds abrasion marks – Skipping final inspection under polarized light misses stress fractures invisible under normal lighting

Avoid those pitfalls by building buffer time into your production schedule—it pays off big time down the line.

FAQs about Airless Lotion Pump

How can I stop UV coating from cracking on glass bottles?

Cracking usually starts small—barely visible hairlines that creep along the surface like spiderwebs. To prevent this, the bottle needs reinforcement at its core. A single-step UV shield strengthens the glass itself, while a soft-touch finish cushions against external stress. For brands chasing both beauty and resilience, embossing your logo into a custom mold isn’t just aesthetic—it adds structure where it matters most.

Is acrylic or polypropylene better for airless lotion pumps?

It depends on what speaks louder to you: clarity or endurance.

- Acrylic feels premium in hand—crystal-clear and smooth like polished stone.

- Polypropylene is more rugged; it takes knocks without complaint and keeps costs down during big production runs.

If you’re aiming for upscale elegance with visual appeal, acrylic wins. But if durability and budget are top priorities, polypropylene holds strong under pressure.

Do metallic finishes really help products stand out in stores?

Absolutely—and not just because they shine brighter under retail lighting. Metallic coatings add depth that flat paint simply can’t mimic. When aligned with Pantone standards, these finishes create consistent branding across product lines—a subtle but powerful cue of quality customers pick up on instantly. It’s not about being flashy; it’s about looking intentional.

Why choose an airless pump over fine mist sprayers or foam pumps?

Airless pumps protect what’s inside by keeping air out completely—that means no oxidation creeping in to spoil delicate formulas like serums or foundations. Unlike mist sprayers that expose contents every time they’re used, airless systems push product upward through vacuum pressure alone… preserving potency without needing heavy preservatives. It’s skincare’s quiet guardian: invisible protection with every press of the pump head.