Secrets to Successful 50ml Plastic Bottles Wholesale Purchasing

Avoid leaky disasters and cap catastrophes—get the real scoop on sourcing 50ml plastic bottles wholesale without losing your sanity.

Most folks don’t think twice about packaging—but if you’ve ever dealt with a leaky shipment of lotion bottles or a batch of warped caps that refuse to twist on straight, you know the pain runs deep. When it comes to 50ml plastic bottles wholesale, one wrong decision can mean product recalls, brand embarrassment, and a serious dent in your bottom line. You’re not just buying containers; you’re investing in trust.

Thing is, sourcing the right bottle feels like chasing unicorns through red tape—materials matter (PET plastic? HDPE?), finishes can make or break shelf appeal, and don’t even get me started on closures that pop open mid-transit. But hold up—we’ve got some hot tips from folks who’ve been around this block more times than they’d care to admit… and we’re spilling tea you’ll actually want to sip.

Key Points in Choosing 50ml Plastic Bottles Wholesale Without Regret

- Material Clarity Matters: PET plastic offers unbeatable transparency for showcasing vibrant product contents, while HDPE provides opaque protection for light-sensitive formulas.

- Eco Is the New Premium: Bulk-buying PCR plastic and recycled HDPE/PET blends not only lowers costs but boosts sustainability credentials your customers care about.

- Closures That Click (Not Leak): Choose functional caps—like screw caps with seal rings or pump dispensers—to prevent leaks and elevate user experience during application.

- Custom Touches Build Your Brand: From frosted finishes to custom matte textures and colors, surface treatments can make your packaging pop on crowded retail shelves.

- Shape Up Your Shelf Appeal: Ensure mold precision for cylindrical or square bottle shapes that align with your brand’s personality and product type—from toner to serum to lotion bottles.

- Global Partners Secure Supply Chains: Reliable global exporters keep deliveries consistent—even when demand spikes—ensuring you never go out of stock at a critical moment.

Unlock Hidden Benefits Of Ordering 50ml Plastic Bottles Wholesale In Bulk

Explore how buying small-capacity containers in large quantities can unlock savings, branding power, and sustainability perks for your business.

Maximize cost-savings with PCR plastic bulk purchases

• Bulk purchases slash unit costs—simple math. When you’re ordering thousands of units, even pennies matter. That’s where real savings kick in. • PCR plastic, made from post-consumer resin, is easier on the planet too. It’s not just about price—it’s about perception. • Ordering 50ml bottles in wholesale lots minimizes shipping costs per item and reduces packaging waste. You win twice.

Table: Average Cost Savings by Volume Tier Using PCR Plastic

| Order Volume | Virgin Plastic Unit Cost ($) | PCR Plastic Unit Cost ($) | Total Savings (%) |

|---|---|---|---|

| 10,000 units | 0.23 | 0.18 | 21.7% |

| 25,000 units | 0.21 | 0.16 | 23.8% |

| 50,000 units | 0.19 | 0.14 | 26.3% |

| Over 100,000 | Custom Pricing | Custom Pricing | Up to ~30% |

So yeah—buying big means saving big.

Achieve brand impact through custom color and matte texture

• Want your product to pop? A custom color changes everything—it grabs attention before anyone even reads the label. • A sleek matte texture doesn’t just look premium; it feels premium too. • These visual details give your packaging that “I want to pick this up” factor on crowded shelves. • With small formats like 50ml plastic bottles, those design choices become even more critical—they’re often used for samples or travel kits where first impressions rule.

You don’t need flashy gimmicks when you’ve got smart design working overtime for your brand.

Secure your supply line via a global exporter partnership

✓ Building a solid relationship with a reliable global exporter means fewer headaches during production crunch time. ✓ They know how to navigate customs, scale orders fast, and keep things moving across borders—even when ports get jammed. ✓ A dependable partnership ensures you’re never left hanging without stock during peak seasons or promo launches. ✓ Plus, sourcing wholesale volumes of plastic bottles from international suppliers gives you access to better pricing tiers and more customization options.

Working globally doesn’t have to be risky—it can actually make things smoother if you pick the right partner.

Boost eco-credentials using recycled HDPE and PET blends

Switching to blends of recycled HDPE and PET isn’t just good PR—it’s good business.

Consumers are paying attention—especially when it comes to plastics under the microscope like single-use formats such as 50ml bottles.

These materials reduce environmental impact without sacrificing durability or clarity.

Using them positions your brand as forward-thinking—and trust us, people talk about that stuff online.

A recent study found that products marketed as sustainable are growing significantly faster than conventional goods. Enough said.

By choosing greener materials at scale through wholesale orders, you’re not only cutting costs—you’re raising standards too.

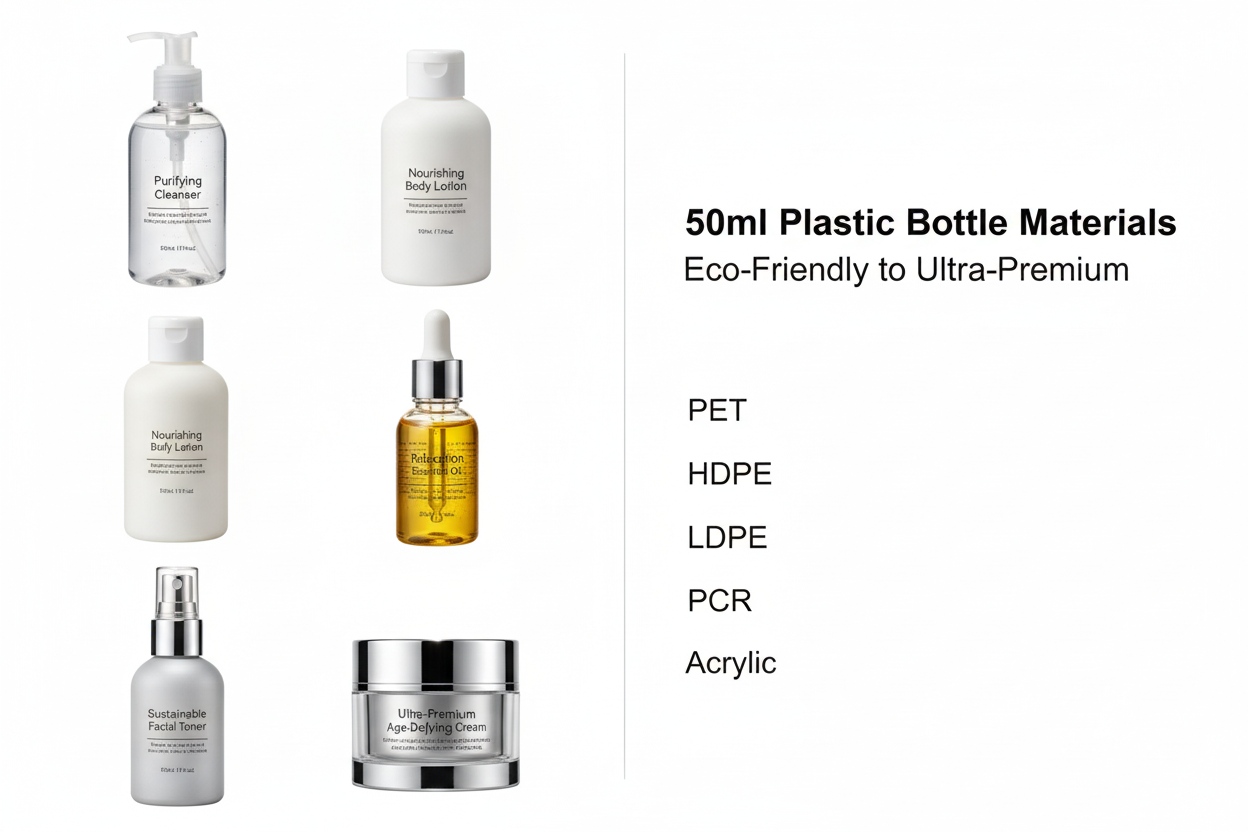

Types Of 50ml Plastic Bottle Materials

From eco-friendly to ultra-premium, the materials used in 50ml plastic bottles wholesale affect everything from feel to function.

PET plastic bottles with clear transparency

- PET plastic is known for its glass-like clarity—perfect for showing off colorful serums or vibrant toners.

- Lightweight and sturdy, these plastic bottles make shipping a breeze without sacrificing looks.

- They’re also recyclable, which helps brands meet growing consumer demand for sustainable packaging.

- Ideal for travel kits, testers, and boutique skincare products where visual appeal matters most.

- Available with various caps and sprayers to match different formulations.

Whether you’re bottling up a citrus face mist or a shimmering body oil, this material lets your product shine through—literally.

HDPE sturdy containers for opaque white lotions

• The thick walls of HDPE containers make them perfect for formulas that need protection from light. Think SPF creams or retinol-based lotions. • These sturdy containers don’t crack under pressure—literally. They handle drops and squeezes like champs. • Plus, they’re compatible with pumps and flip-top caps that customers love for convenience.

According to industry packaging analyses, brands often choose HDPE for durability and compatibility with active ingredients.

That’s not just smart—it’s strategic packaging at its finest.

LDPE flexible dropper design for essential oils

Soft yet strong—that’s what makes LDPE tick. These flexible dropper bottles are tailored for oils that require precision dosing.

Short bursts of lavender? A controlled drip of tea tree? No problem here. The elasticity allows users to gently squeeze out just the right amount every time.

And since LDPE resists chemical interaction better than many plastics, it keeps those high-potency oils stable longer on the shelf.

This combo of flexibility + chemical resistance = perfect fit for essential oil lines looking to stand out in a crowded market. Explore compatible primary packs like a dropper bottle.

PCR-based toner bottles: sustainable UV-coated solutions

Step 1 – Start with post-consumer resin (PCR-based) material that cuts down virgin plastic use. Step 2 – Apply a protective UV coating so your sensitive toner stays potent even under bright lights. Step 3 – Add sleek labeling options—matte finishes or metallic foils—to communicate both eco-consciousness and luxury.

These toner-ready designs meet sustainability goals without compromising performance—a rare blend in today’s overpackaged world.

Brands using PCR bottles aren’t just reducing waste; they’re making a statement about values too.

Acrylic jars with metallized finish for premium creams

- The rigidity of acrylic jars mirrors glass but is far more impact-resistant—ideal when elegance meets practicality.

- That gleaming metallized finish? It screams upscale while shielding contents from light degradation.

- Perfectly sized at 50ml, these jars strike the balance between indulgence and portability.

- Customers often associate this packaging style with prestige skincare lines—and they’re not wrong.

- Available in golds, silvers, rose hues—the options are endless when you want shelf appeal that pops!

For beauty brands aiming at the luxe crowd, Topfeelpack offers tailored solutions that combine glamour with functionality—all without breaking your MOQ budget limits!

Pet Vs. Hdpe: 50ml Bottle Choice

Choosing between PET and HDPE for small-batch packaging? Here’s a quick guide to help you pick the right fit for your product.

PET plastic

- High clarity: PET’s transparency makes it ideal when your product needs to shine through the bottle.

- Sturdy yet lightweight: It offers great strength without adding bulk, perfect for travel-size packs.

- Common uses: • Food-grade items like juices or sauces • Beauty products such as toners or serums

PET, or Polyethylene Terephthalate, is often favored for its sleek finish and retail appeal. If you’re looking to catch eyes on shelves, this type might be your go-to. Plus, it’s widely recyclable, making it a solid choice if sustainability is part of your brand story.

Recent packaging demand snapshots indicate continued growth for small-format PET containers, driven by travel kits and personal care miniatures.

When looking into options like “50ml plastic bottles wholesale,” PET gives you that polished look with durability baked in.

HDPE plastic

HDPE—short for High-Density Polyethylene—has a different vibe altogether. It’s not about showing off; it’s about keeping things safe inside.

• Opaque finish = light-sensitive formulas stay protected. • High chemical resistance = great match for harsh liquids like cleaners or industrial oils.

If you’re bottling something strong-smelling or corrosive, HDPE won’t flinch. Its rugged build handles rough transport without cracking under pressure.

Some common applications include:

- Household detergents

- OTC pharmaceuticals

- Automotive fluids

The ruggedness of HDPE makes it ideal when function trumps form—especially when sourcing sturdy materials via bulk channels like “plastic bottles wholesale.” Even though it lacks the shine of PET, its resilience is unmatched.

Short runs of HDPE packaging are also popular among niche skincare brands using essential oils that degrade under light exposure—a real concern when packaging sensitive blends meant to last on shelves or bathroom counters alike.

So while PET may win beauty contests, HDPE walks away with the endurance medal every time.

5 Tips For Quality 50ml Plastic Bottles Wholesale Selection

Choosing the right small-volume packaging? It’s not just about looks. Here’s how to spot quality when picking out 50ml plastic bottles for your product line.

Ask for PCR and PET material certifications

- Request documentation proving use of PCR (Post-Consumer Resin) and virgin-grade PET.

- Confirm compliance with FDA or EU food-contact safety standards.

- Look for suppliers who meet ISO 14001 environmental management benchmarks.

Brands that back their packaging with legit material certifications are serious about sustainability. Don’t just take their word—ask to see the paperwork. Many buyers now prioritize verified recycled content in primary packaging.

Evaluate glossy smooth versus matte texture finishes

- Glossy finish:

- Reflects light, ideal for premium skincare branding

- Enhances visibility on retail shelves

- Matte finish:

- Soft-touch feel, gives off a minimalist vibe

- Reduces fingerprint smudging

Both finishes have their perks depending on your brand image. A glossy surface screams luxury, while matte texture feels grounded and modern. If you’re bottling high-end toners or serums, glossy might be your go-to. But if you’re all about clean beauty aesthetics? Matte’s where it’s at.

Verify cylindrical round and square shaped mold accuracy

Mold precision is non-negotiable when it comes to consistent bottle shape and function. Here’s what to check:

| Shape Type | Common Use Case | Tolerance Level (mm) | Mold Defect Risk |

|---|---|---|---|

| Cylindrical | Serums & lotions | ±0.3 | Low |

| Round | Toners & facial mists | ±0.2 | Medium |

| Square | High-viscosity liquids | ±0.4 | High |

Even tiny deviations in mold alignment can mess with cap fit or label placement. Always ask for sample batches before committing to bulk orders of any shape—especially if you’re going square, which tends to warp more easily during cooling.

Consider screw cap strength and flip top cap functionality

• Screw caps need tight threading—test torque resistance by twisting them open/closed repeatedly • Flip top caps should snap shut securely without leaking under pressure • Check compatibility between cap type and bottle neck design

Caps aren’t just closures—they’re part of the user experience too. A weak-threaded screw cap can be a dealbreaker, especially if customers are tossing bottles into bags or drawers. And a flimsy flip-top? That leads straight to leaks (and bad reviews). Make sure both types pass basic drop tests before giving them the green light.

Match bottle design to your serum, toner, or lotion needs

Different products call for different designs—and yes, size matters even at just fifty milliliters.

• Got a lightweight toner? Go with slim-necked bottles that control flow rate • Rich serum formulas? Airless pump-compatible shapes keep things hygienic • Thick lotions? Wider mouths make scooping easier

When choosing your bottle style from wholesale options in this volume range, think beyond appearance. Functionality tied closely with formula consistency makes all the difference in daily use—and keeps your customers coming back instead of switching brands because they couldn’t get that last bit of lotion out of the tube.

Frequent Leakage? Secure Caps For 50ml Bottles Wholesale

Tired of dealing with leaks or messy dispensing? Here’s how to lock down your 50ml plastic bottles wholesale packaging game with smarter, tighter cap solutions.

Screw caps with integrated seal rings

- Leak-proof assurance: The inner integrated seal rings compress tightly against bottle openings, locking out air and keeping contents fresh.

- Durable material: Most screw caps are made from high-grade polypropylene, which resists cracking under pressure and survives rough transit.

- Universal fit: These closures suit a wide range of plastic bottles, especially around the compact 50ml size used in cosmetics and lab samples.

- Tamper evident options: Some variants come with breakable bands to show first-time use clearly.

- Bulk-ready: Perfect for buyers seeking reliable closure systems at scale—especially when ordering through a trusted source like Topfeelpack.

Flip top cap designs for one-handed operation

You’re juggling a bag, your phone, maybe even a toddler—and now you need toner. That’s where the magic of the flip-top comes in.

• Pop open with just a thumb—no twisting needed. • The hinge design stays put; no loose pieces falling off. • Smooth dispensing hole prevents sudden surges or spills.

These kinds of ergonomic, easy-open flip top caps work wonders on travel-sized lotions or hand sanitizers. With their compact build and snap-shut reliability, they’re tailor-made for busy lifestyles and quick-grab moments involving smaller format containers like those found in the typical 50ml bottle range.

Pump dispensers for controlled lotion dosing

Ever pumped too much moisturizer into your palm? Yeah—us too. That’s why precision matters.

- A well-calibrated spring mechanism controls product output every time you press down.

- The nozzle design channels flow directly—no side dribbles or awkward angles.

- Locking heads prevent accidental discharge during shipping or travel.

Industry sources note that well-designed pump dispensers can help reduce overuse and waste, enhancing both sustainability and satisfaction.

Spray nozzles ideal for toner distribution

Spritz evenly without soaking your face—or wasting product—with these smartly engineered sprayers:

- Fine mist atomizers ensure light but full coverage across skin surfaces.

- Adjustable spray heads allow control over distance and intensity.

- Designed specifically for fluid products like toners or facial mists commonly bottled in small-capacity vessels such as the standard cosmetic-sized bottle format (50ml range, anyone?).

- Compatible with PET and HDPE bottles used widely across skincare lines.

These types of precision-engineered spray nozzles aren’t just practical—they’re essential when product application needs to feel refined yet efficient.

Dropper inserts ensuring precise essential oil drops

Tiny bottles call for tiny control—and that’s exactly what dropper inserts deliver.

A few drops at a time—that’s all you need when working with potent oils. Each insert sits snugly inside the neck of your glass container. You tilt; it measures out droplets precisely—no glugging messes here.

Whether you’re bottling lavender blends or vitamin serums, these handy little tools make sure each drop counts—especially important when working within narrow-necked formats like those found in many compact glass units around the familiar 50ml capacity zone. See how droppers are tuned for controlled flow.

50ml Bottle Mastery

Unlock the tricks to stand out with small-format packaging that punches above its weight.

Master supply chain with a reliable plastic distributor

- Inventory gaps kill momentum—partnering with a dependable plastic distributor keeps things humming.

- Look for reliability, not just low cost. A flaky supplier means missed launches, delayed orders, and angry customers.

- Choose distributors who understand logistics inside out. That includes real-time tracking, smart warehousing, and regional delivery options.

- Check if your supplier offers flexible MOQs.

- Ask about emergency restock protocols—they matter more than you think.

- Verify their experience handling wholesale accounts for personal care or cosmetic brands.

Avoid overstocking by syncing your forecasts with their production schedules. ✔️ Ensure they use high-quality resins for your supply chain to stay consistent.

A good partner doesn’t just ship boxes—they become part of your brand’s rhythm. Topfeelpack works closely with brands to reduce lead times while keeping every pallet traceable.

Streamline filling: pump dispenser assembly tips

• Want smooth production? Nail the filling process early—it’s where most bottlenecks hide. • Misaligned nozzles or sticky pumps ruin batches fast; precision beats speed every time.

- Pre-test each batch of pump dispensers before full-scale assembly begins.

- Train staff on torque specs—over-tightening leads to micro-leaks that show up weeks later.

- Use semi-automated lines if you’re scaling beyond hand-filling but not ready for full automation yet.

Tip: Always inspect nozzle alignment post-fill—it saves hours down the line.

Keep an eye on potential leakage points during assembly; even tiny missteps here can snowball into major returns later on. The right tools combined with sharp-eyed operators make all the difference when working at scale in the world of 50ml formats. For premium dosing and hygiene, explore an airless pump bottle.

Brand differentiation via frosted finish and custom color

• A sleek frosted finish screams premium without saying a word—perfect for skincare lines targeting upscale markets. • Pair it with a bold or muted custom color, depending on your vibe—earth tones are trending hard right now.

Grouped ideas:

- For minimalists → Matte white + subtle frost

- For naturals → Sage green + soft amber tint

- For bold brands → Deep navy + gloss-free black pump

Design isn’t fluff—it’s strategy wrapped in aesthetics. Your packaging is often the first thing people notice online, especially when scrolling past dozens of similar-sized bottles in search results tied to “50ml” formats. Nail that visual hook and watch conversions jump.

Packaging doubles as marketing these days—and those tiny touches like finish and tone speak volumes about what kind of experience customers can expect inside that bottle.

Ensuring quality through UV coating and matte texture checks

UV protection matters more than ever—especially as more products sit under bathroom lights or get tossed into travel bags exposed to sun glare daily.

- Start by inspecting every batch’s matte texture under angled lighting.

- Test durability by running scratch tests across coated surfaces.

- Confirm consistency using gloss meters calibrated weekly against ISO benchmarks.

- Validate adhesion strength between layers using pull-off adhesion testing methods common in industrial QC labs.

- Keep records digitally so trends don’t slip through unnoticed over time.

- Conduct random spot inspections monthly—even trusted suppliers need oversight sometimes.

As packaging research shows, tactile finishes can elevate perceived value—while UV coatings improve scratch and abrasion resistance over time.

When you’re dealing with smaller formats like travel-size bottles, every inch counts, literally and visually—and protective layers aren’t just functional; they’re a branding tool too.

FAQs about 50ml Plastic Bottles Wholesale

What makes buying 50ml plastic bottles wholesale a smart move? Bulk purchasing isn’t just about saving money—though it does that too. It’s about consistency. Your production line runs smoother when every bottle is identical, and your brand feels more polished when packaging doesn’t vary from batch to batch. Plus, ordering in bulk opens the door to custom finishes like soft matte or frosted textures that smaller orders often can’t access.

Should I go with PET or HDPE for my cosmetic packaging?

- PET gives you crystal-clear transparency—perfect if your serum has a rich hue or shimmer you want people to see before they even open the cap

- HDPE leans toward durability and protection; its opaque body shields light-sensitive creams and lotions Choosing between them depends on what story your product needs to tell at first glance.

How do I stop leaks during shipping? A single leak can ruin an entire shipment—and your reputation. That’s why closures matter:

- Screw caps with seal rings keep things tight under pressure

- Flip tops are practical but still secure for everyday use

- Pumps offer clean dispensing while locking mechanisms prevent spills en route

Each closure type serves a different purpose, so think through how your customers will interact with the bottle after it leaves the warehouse.

Can I customize my wholesale order of 50ml plastic bottles? Absolutely. You’re not stuck picking off a shelf—you can request specific colors, textures like velvet-soft touch coatings, or high-gloss UV finishes that catch light in all the right ways. Even metallized jars are possible if you’re aiming for something bold and premium-looking.

Why ask for PCR and PET certifications before placing an order? Because trust matters more than ever now. Certifications prove recycled content claims aren’t just marketing fluff—they’re real commitments backed by documentation. If sustainability is part of your brand promise (and let’s be honest—it should be), verified materials help reinforce that message without saying a word on the label.

Do pump dispensers slow down production lines during filling? Not necessarily—but only if they’re preassembled correctly before hitting your factory floor. When done right, pumps actually streamline operations by reducing manual steps later on. The trick lies in working closely with suppliers who understand both design precision and manufacturing flow—it’s those small efficiencies that make big differences over time.

- SpecialChem – Polyethylene Terephthalate (PET): Uses, Properties & Processing - https://www.specialchem.com/plastics/guide/polyethylene-terephthalate-pet-plastic

- Thermo Fisher Scientific – High-Density Polyethylene (HDPE) Labware - https://www.thermofisher.com/us/en/home/life-science/lab-plasticware-supplies/plastic-material-selection/high-density-polyethylene-hdpe-labware.html

- U.S. EPA – Use ISO 14021 Definition for Post-Consumer Recycled (PCR) Content (slides) - https://www.epa.gov/sites/default/files/2020-06/documents/slides_webinar_procurement_recycled-content_products.pdf

- Association of Plastic Recyclers – Recycled Plastic Content Requirements (Policy Hub) - https://plasticsrecycling.org/tools-and-resources/policy-hub/policy-priorities/recycled-plastic-content-requirements/

- NYU Stern Center for Sustainable Business – Sustainable Market Share Index™ 2024 (Slides) - https://www.stern.nyu.edu/sites/default/files/2025-04/SMSI%202024%20Slides%20to%20share_%20FINAL%20ACCESSIBLE.pdf

- PCI Magazine – UV Coatings on Plastics Improve Scratch & Abrasion Resistance - https://www.pcimag.com/articles/107018-uv-coatings-on-plastics

- RIT Journal of Applied Packaging Research – Consumer Perception of Tactile Packaging - https://repository.rit.edu/japr/vol7/iss1/1/

- APC Packaging – Plastic Pumps for Skincare: Reduced Product Waste - https://techcenter.apcpackaging.com/plastic-pumps-for-skincare

- O.Berk – What’s Inside a Fine Mist Sprayer and How It Works - https://www.oberk.com/packaging-crash-course/whats-inside-a-fine-mist-sprayer

- Carow Packaging – Droppers for Essential Oils: How Inserts Should Work - https://carowpackaging.com/droppers-for-essential-oils-how-inserts-should-work-for-your-products/

- PET Resin Association (PETRA) – About PET & Recycling - https://petresin.org/

- Mesa Labs – Cap Torque Testing: Standards & Regulations (overview) - https://mesalabs.com/torque-news/cap-torque-testing-standards-and-regulations