- Home

- News

- Plastic recycling is broken – new plastic alternatives are key to the fight against microplastics

Plastic recycling is broken – new plastic alternatives are key to the fight against microplastics

Recycling and reuse alone will not solve the problem of increased plastic production. A broad approach is needed to reduce and replace plastics. Fortunately, alternatives to plastic are emerging with significant environmental and commercial potential.

Over the past few years, sorting plastic for recycling has become a daily chore for many individuals and organizations willing to contribute to the environment. This is clearly a good trend. However, few people know what happens to plastic when garbage trucks speed up.

In this article, we discuss the problems and potential of plastic recycling, as well as the tools we can use to address the global plastic problem.

Recycling can’t cope with growing plastic production

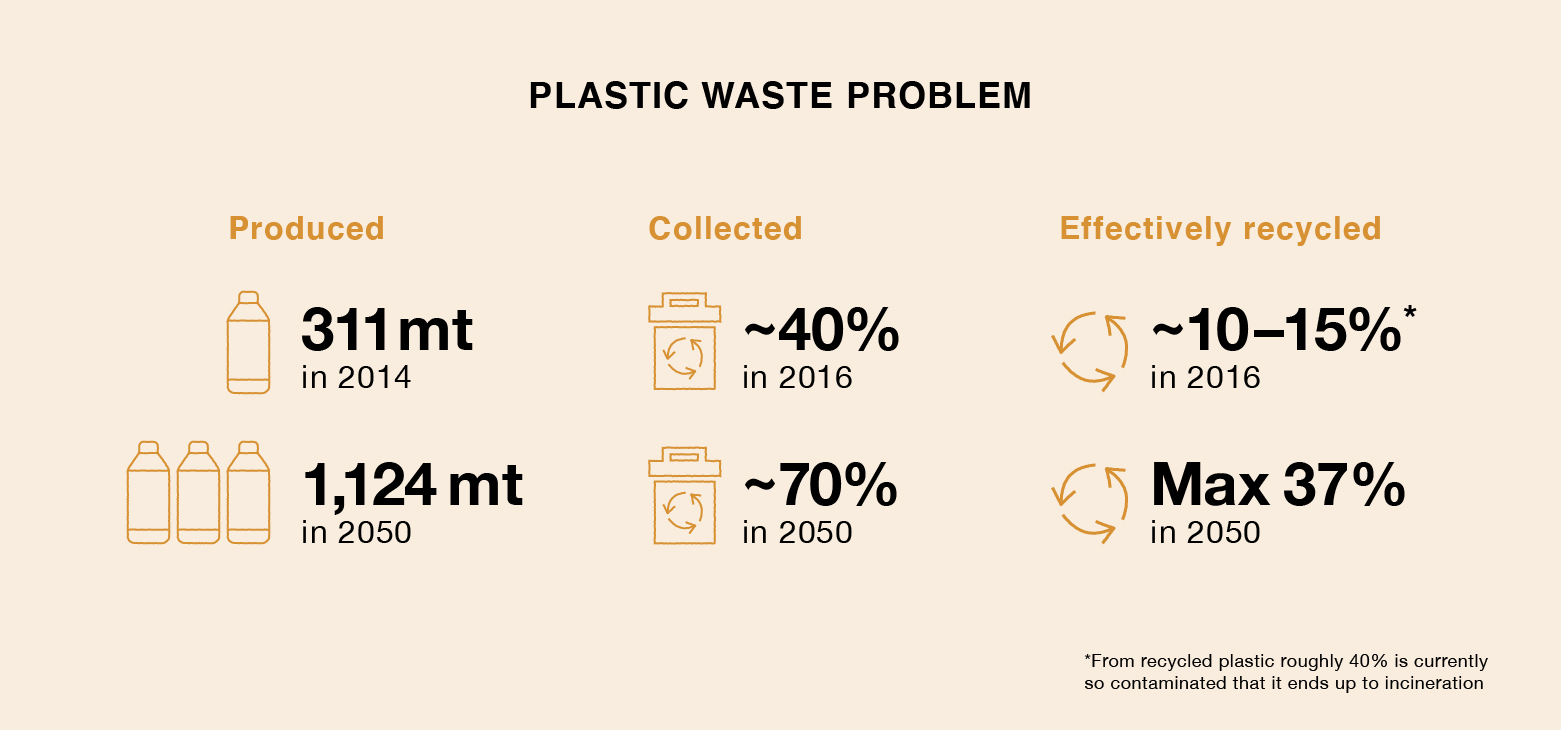

Production of plastics is expected to at least triple by 2050. The amount of microplastics released into nature is about to grow significantly as the existing recycling infrastructure cannot even meet our current production levels. Increasing and diversifying global recycling capacity is necessary, but there are several issues that prevent recycling from being the only answer to the growth of plastic production.

Mechanical recycling

Mechanical recycling is currently the only recycling option for plastics. While collecting plastic for reuse is important, mechanical recycling has its limitations:

* Not all plastics collected from households can be recycled through mechanical recycling. This causes the plastic to be burned for energy.

* Many plastic types cannot be recycled due to their small size. Even if these materials can be separated and recycled, it is often not economically viable.

* Plastics are becoming more complex and multi-layered, which makes it difficult for mechanical recycling to separate different parts for reuse.

* In mechanical recycling, the chemical polymer remains unchanged and the quality of the plastic gradually decreases. You can only recycle the same piece of plastic a few times before the quality is no longer good enough for reuse.

* Inexpensive fossil-based virgin plastics are less expensive to produce than to collect, clean and process. This reduces market opportunities for recycled plastics.

* Some policymakers are relying on exporting plastic waste to low-income countries rather than building adequate recycling infrastructure.

Chemical recycling

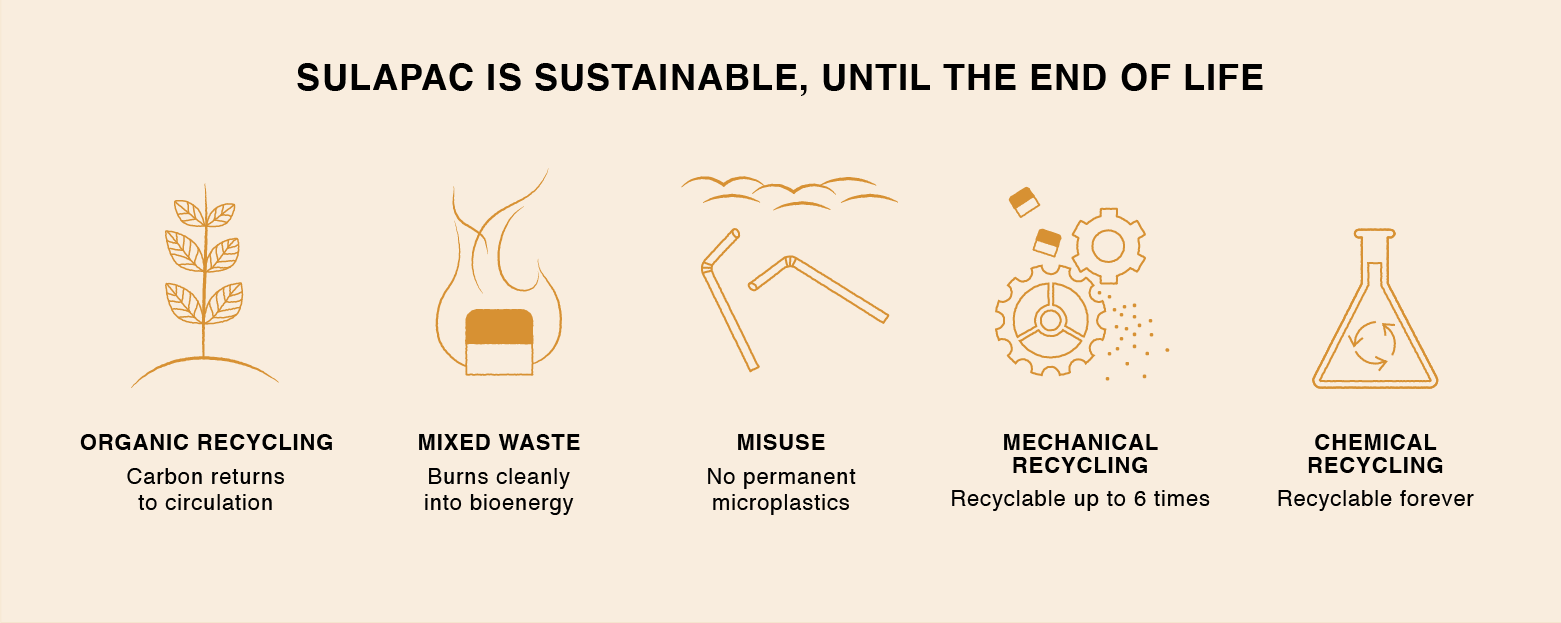

The current dominance of mechanical recycling has slowed the development of chemical recycling processes and required infrastructure. Technical solutions for chemical recycling already exist, but are not yet considered an official recycling option. However, chemical recycling shows great potential.

In chemical recycling, the polymers of the collected plastics can be altered to improve existing polymers. This process is called an upgrade. In the future, converting carbon-rich polymers into desired materials will open up possibilities for both traditional plastics and new bio-based materials.

All forms of recycling should not rely on mechanical recycling, but should play a role in creating a well-functioning recycling infrastructure.

Plastic recycling does not address microplastics released during use

In addition to end-of-life challenges, microplastics create problems throughout their life cycle. For example, car tires and synthetic textiles release microplastics every time we use them. In this way, microplastics can get into the water we drink, the air we breathe and the soil we farm. Since a large proportion of microplastic pollution is related to wear and tear, it is not enough to deal with end-of-life issues through recycling.

These mechanical, technical, financial and political issues related to recycling are a blow to the global need to reduce microplastic pollution in nature. In 2016, 14% of the world’s plastic waste was fully recycled. About 40% of the plastic collected for reuse ends up in incineration. Clearly, other ways to supplement recycling must be considered.

A holistic toolbox for a healthier future

Fighting plastic waste requires a broad approach, in which recycling plays an important role. In the past, the traditional formula for a better future was “reduce, recycle, reuse”. We don’t think that’s enough. A new element needs to be added: replace. Let’s take a look at the four R’s and their roles:

Reduction: With plastic production soaring, global policy measures to reduce the use of fossil plastics are critical.

Reuse: From individuals to countries, reusing plastics is possible. Individuals can easily reuse plastic containers, such as freezing food in them or filling empty soda bottles with fresh water. On a larger scale, cities and countries can reuse plastic bottles, for example, multiple times before the bottle reaches its end of life.

Recycling: Most plastics cannot be easily reused. A versatile recycling infrastructure capable of handling complex plastics in an efficient manner would significantly reduce the growing problem of microplastics.

Replacement: Let’s face it, plastics have functions that are integral to our modern way of life. But if we want to keep the planet healthy, we must find more sustainable alternatives to fossil plastics.

Plastic alternatives show huge environmental and commercial potential

At a time when policymakers are increasingly interested in sustainability and carbon footprints, there are multiple ways to bring about change for individuals and businesses. Eco-friendly plastic alternatives are no longer an expensive alternative but an important business advantage to attract customers.

At Topfeelpack, our design philosophy is green, environmentally friendly and healthy. We want to make sure you don’t have to worry about packaging or sacrificing product quality for the environment. When you use Topfeelpack, we promise you:

Aesthetics: Topfeelpack has a sophisticated look and feel that makes it stand out. With the unique design and material, consumers can feel that Topfeelpack is no ordinary cosmetic packaging company.

Functional: Topfeelpack is of high quality and can be mass produced with your existing machinery for plastic products. It meets demanding technical requirements and is suitable for a variety of applications, including skin care products of various ingredients.

Sustainability: Topfeelpack is committed to producing sustainable cosmetic packaging that reduces plastic pollution at the source.

It’s time to switch from environmentally harmful types of plastic to sustainable alternatives. Are you ready to replace pollution with solutions?