Ultimate Guide to Hand Lotion Pump Dispenser Materials

Choosing the right hand lotion pump dispenser isn’t just about getting product from bottle to palm—it’s a silent handshake with your customer, a split-second impression that says, “Hey, this brand knows what it’s doing.” But behind that smooth pump action? A wild world of plastics, resins, and eco-friendly alternatives all wrestling for a spot on your production line.

Some materials play nice with thick shea butter formulas but crack under citrus oils; others look sleek on the shelf but cost more than they’re worth in freight fees. It’s like picking the right shoes for a marathon—you want durability without blisters and style without sacrificing performance.

If you’re sourcing packaging for scale or prepping to pitch buyers at trade shows, you better know your HDPEs from your bio-polys. This guide is here to break it down—no fluff, no filler—just real talk about materials that work as hard as you do.

Key Points in the Material World of the Hand Lotion Pump Dispenser

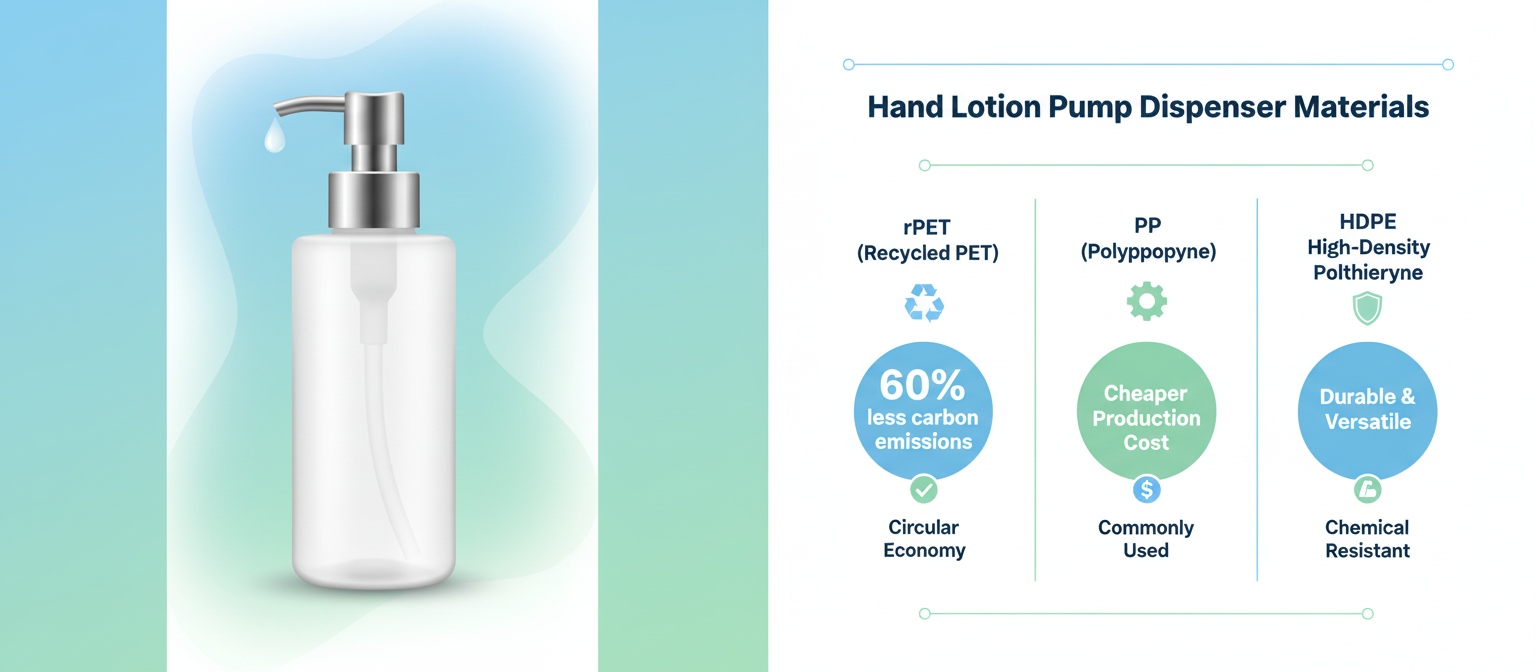

➔ Material Matchmaking: Choosing between HDPE and polypropylene affects flexibility, chemical resistance, and durability—critical for matching with lotion viscosity.

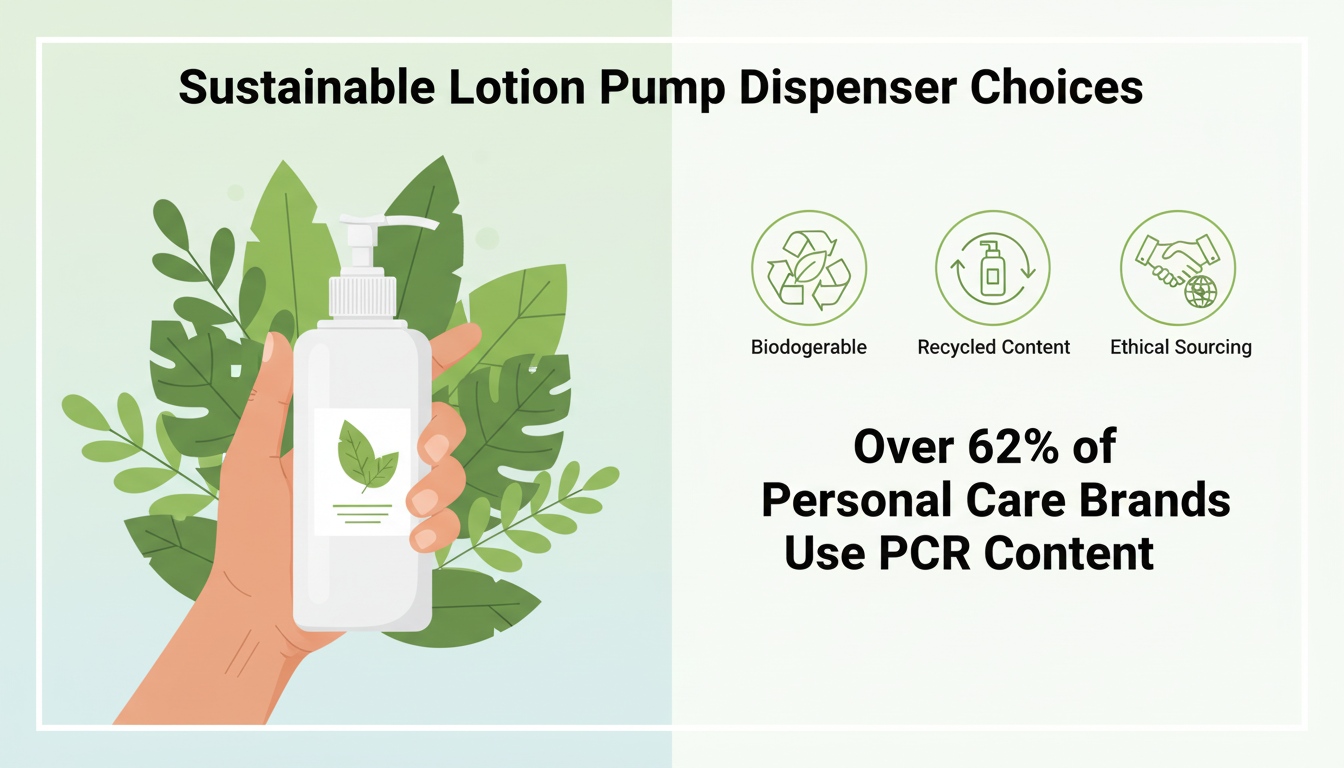

➔ Eco Moves Matter: Bio-based polyethylene and post-consumer recycled PET are leading choices for brands focused on sustainability without sacrificing performance.

➔ Steel the Spotlight: Stainless steel dispensers offer a hygienic, corrosion-resistant option with premium visual appeal that elevates brand presence.

➔ Tech That Protects: Airless pump technology ensures product integrity, extending shelf life and preventing contamination—essential for sensitive formulas.

➔ Cost vs. Commitment: Investing in FDA-compliant and ISO-certified materials pays off long-term through reduced waste, fewer recalls, and better market trust.

Understanding Hand Lotion Pump Dispenser Types

From foam to airless pumps, each type of hand lotion pump dispenser has its own groove. Let’s break down how they work and what makes them tick.

Key Features of Lotion Pump Dispensers

• Built-in locking features help avoid leaks during travel.

• Adjustable output volume lets brands customize user experience.

• Durable materials like PP and PETG stand up to thick creams and daily use.

- A good dispensing mechanism ensures smooth flow without clogging.

- The design must suit both aesthetics and function—think ergonomic shape plus reliable spring action.

– Available in matte, glossy, or metallized finishes that enhance shelf appeal.

A well-designed lotion pump balances efficiency with comfort. It’s not just about pushing product out—it’s about doing it smoothly, every time.

Short-stroke pumps are great for low-viscosity lotions; long-stroke ones handle thicker formulas better. Some even come with twist-locks for added safety.

Grouped by feature sets:

- Materials & Durability: Polypropylene body, stainless steel springs

- Design & Ergonomics: Thumb-friendly tops, smooth rebound

- Performance: Controlled output, no-drip valves

Expect consistent delivery from high-end options like Topfeelpack’s customizable pumps—they blend form with function effortlessly.

How Foam Pump Mechanisms Work

• Air gets pulled into the system through a small valve near the top.

• This mixes with the liquid inside the chamber to create foam on each press.

• A mesh screen helps break up bubbles into that creamy texture we all love.

- The pump stroke draws both air and liquid simultaneously.

- Inside the mixing chamber, pressure builds as components combine evenly.

– That soft lather? It comes from precise engineering—not luck.

Foam pumps rely on coordinated airflow and liquid ratio control to consistently whip up light foam with minimal mess or waste.

You’ll notice:

- Lightweight feel after dispensing

- No dripping due to internal seals

- Ideal for facial cleansers or mousse-like lotions thanks to balanced pressure systems inside the pump head

Grouped by technical parts:

- Air Intake Valve: Draws ambient air into mixing area

- Mixing Chamber: Combines liquid solution + air seamlessly

- Dispensing Nozzle: Releases finished foam in clean bursts

If you’re working with low-viscosity products that need a rich feel without overuse, this is your go-to system for any modern-day skincare line using a smartly engineered foam pump setup.

The Benefits of Airless Pump Technology

| Feature | Traditional Pumps | Airless Pumps | Benefit Type |

|---|---|---|---|

| Product Exposure | High | None | Shelf Life |

| Dosing Accuracy | Moderate | High | Consistency |

| Residual Waste | Up to 10% | <2% | Sustainability |

| Contamination Risk | Present | Minimal | Hygiene |

Airless systems are game changers when it comes to preserving formula integrity in today’s eco-conscious beauty space. These clever dispensers prevent oxidation by eliminating air contact entirely—your lotion stays fresh longer without needing heavy preservatives.

Grouped advantages:

- Product Preservation: Airtight container protects against spoilage

- Consistent Dosage: Delivers exact amounts every time

- Minimal Waste: Push-up piston ensures nearly full usage of contents

The best part? You don’t have to tip or shake anything—the vacuum mechanism does all the work behind the scenes while keeping things tidy on your countertop or in your travel bag.

Whether you’re packaging anti-aging serums or luxury creams, an advanced airless system elevates both performance and perception—and Topfeelpack nails this combo every time with their sleek designs built around true consumer needs.

Comparing Trigger Spray Applicators and Fine Mist Sprayer Heads

Trigger sprayers pack punchy delivery power—perfect for hair detanglers or body sprays where coverage matters more than subtlety. In contrast, fine mist sprayers shine when you want delicate diffusion across skin surfaces like toners or setting sprays.

You’ll notice key differences:

- Trigger sprayers offer larger droplet size and broader spray pattern

- Fine mist heads produce micro-droplets ideal for lightweight applications

- Ergonomics vary—a trigger grip suits long sprays; finger-top misters suit short bursts

Grouped comparison points:

- Spray Pattern & Coverage Area

- Trigger: Wide fan-like distribution

- Mist: Narrow cone-shaped dispersion

- Droplet Size

- Trigger: Coarse droplets (~300μm)

- Mist: Ultra-fine (~50μm)

- Ergonomics

- Trigger: Full-hand squeeze

- Mist: Finger tap action

Each has its place depending on product type—but if you’re going for elegance plus ease-of-use in personal care items, fine mist wins hands down while still giving off that luxe vibe customers crave.

References

- Bio-based Polyethylene Plastics – Packaging Digest – https://www.packagingdigest.com/sustainable-packaging/what-are-bio-based-plastics

- PET Recycling Overview – Plastics Recycling Org – https://www.plasticsrecycling.org/

- Stainless Steel Sanitation Benefits – NCBI – https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7647030/

- PETG Material Properties – Omnexus – https://omnexus.specialchem.com/polymer-properties/properties/chemical-resistance/petg-polyethylene-terephthalate-glycol

- Airless Bottles and Tech – Topfeelpack Airless Bottles – https://www.topfeelpack.com/airless-bottle/

- Lotion Bottle Solutions – Topfeelpack Lotion Bottles – https://www.topfeelpack.com/lotion-bottle/

- Fine Mist Sprayer Example – Topfeelpack Fine Mist – https://www.topfeelpack.com/pb23-pet-360-spray-bottle-fine-mist-sprayer-product/

- Airless Pump Bottle – Topfeelpack Product – https://www.topfeelpack.com/airless-pump-bottle-for-cosmetics-and-skincare-product/

- Product Listings – Topfeelpack Products – https://www.topfeelpack.com/products/